DANREL Ultrasonic plastic welding machine is widely used in automotive industry, electronic industry, medical industry, household appliances, woven apparel, office supplies, packaging industry, toy industry, and so on.

Automotive industry: plastic body parts, car doors, automotive dashboard, lights, mirrors, sun visor, interior parts, filters, reflective material, reflective spike, bumper, cable, plastic filter for motorcycle , Radiator, brake fluid tank, oil cups, water tanks, fuel tank, air hose, exhaust purifiers, the tray plate, and so on.

Plastic Electronics: prepaid water meters, communications equipment, cordless phones, mobile phone accessories, cell phone case, battery case, charger, maintenance valve regulated lead-acid batteries, 3-inch floppy disk, U disk, SD card, CF card, USB connection, Bluetooth devices, and so on.

Stationery: folder, album, folding boxes, PP hollow board, pen loops, ink cartridges, toner cartridges, and so on.

Medical and Daily products: watches, kitchen utensils, oral liquid bottle caps, drip caps, mobile phone accessories, golden soft brush, and daily necessities, handle, security caps, cosmetics bottle, coffee pot, washing machines, air dehumidifiers, Electric irons, electric kettles, vacuum cleaners, speakers, cover and metal face grille and other civil engineering and so on.

Health products: children's products, air mattresses, clothes hangers, gardening supplies, kitchenware sanitary ware, shower, shower head, and so on.

Vibrator Bowl(Optional Device)

Vibrator bowls for automatically feeding the plastic parts, orientation capable. Customized based on the thermoplastic parts size and geometry.

Remarks: Optional device, please send us drawings or samples to confirm.

MACHINE PARTS

Name: PLC touch screen;

PLC/HMI touch screen - quick, easy parameter input and adjustment.

Automatic Robot Arm/Unloader

1. Equipped with an automated unloader to pick up the welded products.

2. The Unloader can be equipped with suction cup or the clamp.

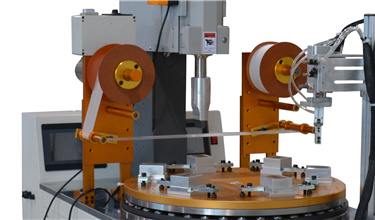

Automatic Rotation Table

1. Automatic cam indexing table.

2. Automated indexing rotary table with 4/6/8/10 working stations.

3. The rotary table size is based on the size of the welding products.

Automatic Foil Feeder

Function: to protect the products surface from the damage of the ultrasonic welding. The film moving distance is adjutable.

Remarks: An optional device.

Pneumatic Components

1. Name: Air Cylinder

Brand: FESTO

2. Name: Pressure Regulator

Brand: SMC